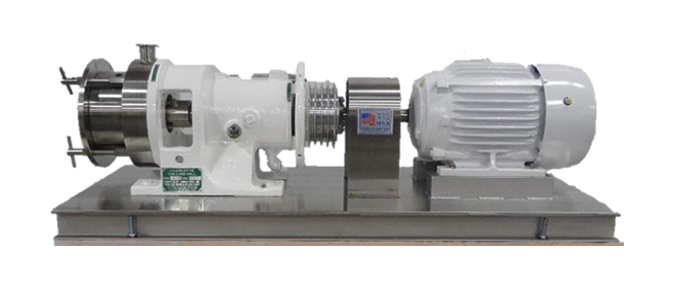

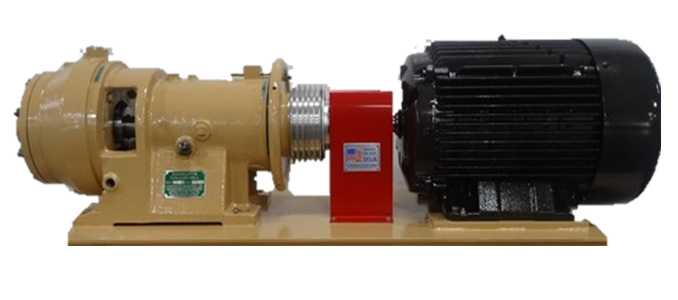

All Charlotte Colloid Mills are manufactured utilizing skilled craftsmanship and the latest in high performance construction materials. The Charlotte G (Industrial) series is available with type 316 stainless steel or hardened steel working components in the product area. The SD Models (Sanitary Design) are designed to handle food and other personal products under the strictest sanitary conditions. Complete type 316 stainless steel construction is used throughout the product area, equipped with triclamp sanitary connections, and a special rotary shaft seal.

| "SD" Series Applications | |

|---|---|

| Mayonnaise/Dressings | Syrups |

| Peanut Butters/Nut Butters | Tomato Products |

| Fish Meals | Gravies/Sauces |

| Aqueous suspensions | Gels |

| Sunscreens | Ointments |

| Dispersions | Fragrances |

| Toiletries | Potted Meats |

| Meat Pâtés | Toothpastes |

| Wax Emulsions, i.e., Lipstick, Mascaras, Topical Creams and Lotions | |

| Hair Care Products, Shampoos, Conditioners | |

| "G" Series Applications | |

|---|---|

| Bitumen Emulsions | Road Paving Emulsions |

| Industrial Applications | Roofing Compounds/Clay Slips |

| Sealers/Coal Tar | Rustproofing Compounds |

| Latex Emulsions | Adhesive Compounds |

| Wax Emulsions | Greases/Lubricants |

| Lithium Complex Greases | Pigment Dispersions |

| Silicone Emulsions | PVC Slurry |

| Waterproofing Compounds | Paper Coatings |

| Thermal Plastic Materials | |

All Charlotte Colloid Mills are designed for trouble-free operation. The average life of our equipment, with good care, is many decades. The Charlottes can be cleaned in place. Saves time, saves money.

© 2024 Colloid Mill

Web Site Design & Development by Logic Web Media